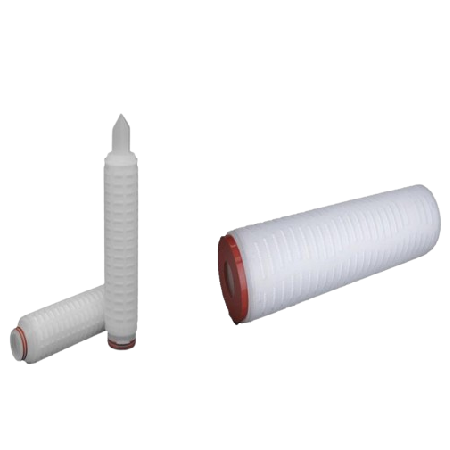

Pleated Filter Cartridges

JFT Pleated Filter Cartridges are designed to optimize the surface area of the PP media for higher flow rate, lower clean Delta P and longer Service life. The Filter provides more surface area due to its pleated design.

Applications for these are available across food & beverages, pharmaceutical, semiconductor and other demanding process applications. All PP construction and gradient density micro-fiber media provide excellent removal efficiencies and high contaminant holding capacities. All materials used in this filter cartridge are CFR-21 complaint so, it is safe to use for food contact purposes.

Applications

- Pharmaceutical Pre filtration

- DI Water

- Process / Rinse water

- Fine Chemicals

- Solvent and gas pre filtration

- Lens Coatings

- DE Trap filters in Breweries

- CD / DVD media

Features & Benefits

- Meets USP 24 Class VI biological test for plastics

- High Filtration Efficiency–99.9% (Beta 1000)

- Graded pore density graded density media for high dirt holding capacity

- Fixed pore construction, Eliminates unloading at maximum differential pressure

- Option of various Gasket/ ’O’-ring materials, Compatible with many fluids

- Pleated Glass Fiber media is ideal for retention of extremely small particles and colloidal materials

- Economical & efficient filtration

Filter Specification

Media: Polypropylene (PP)

Inner Core: Polypropylene (PP)

End caps: Polypropylene (PP)

Cage: Polypropylene (PP)

Filter Efficiency: 0.2, 0.45, 1, 2.5, 5, 10, 20, 25, 40, 50, 100 micron

O Rings / Gaskets(for SOE): Buna N, EPDM, Silicone, Viton, Teflon Encapsulated Viton ‘O’ rings

Dimensions

Nominal lengths: 9.75, 10, 20, 30, 40 inches

Diameter: ID/OD: 1.1” (28 mm) / 2.7” (70 mm)

End connections: DOE (standard) / SOE (optional)

Max operating temperature: 80°C

Max Change Out Differential Pressure: 75 PSID (5.2 bar at 21OC); 40 PSID (2.8 bar at 80°C)

Recommended Change out differential pressure: 35 PSID